Examples nut running technology -

Crossfire of needs - unique solutions!

|

|

2-fold engine-pump nut runner with fixed pitch

Use: Nut running of fuel injection pumps on diesel engines at DAF

Speciality: The supply of the nut runner in the area is made by a preset bevel and an X-Y movement in a crossbar chassis. The handling is extremely low-friction and workers friendly.

Nut runner mechanics bent around the assembly angle on heavy load ball rotating guidance, telescope suspension with rope balancer and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moment 150 Nm |

|

|

2-fold piston rod nut runners with fixed pitch

Use: Screw connection of engine piston rod at diesel engines at Liebherr

Speciality: The turning of the nut runner unit is made by turning camps at the sides of the nut runner. Over adjustable friction assemblies the actuating forces for the lagging can be adjusted. Thus the nut runner in each position stops.

Nut runner mechanics inclinable over adjustable friction camps. Telescope suspension with rope balancer and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torques moments: 320 Nm |

|

|

4-fold nut runner Ford Turkey |

|

|

4-fold U-bolt nut runner with adjustable pitches

Anwendung: Screw connections of U-bolts at Schmitz Cargobull

Besonderheit: The system is built with adjustable pitches, so that the needed U-bolt pitches can be realized with this mechanics. Arbitrary nut runners can be used. To avoid bending forces on the standard nut runners special supporting extensions are used. Thus increases the endurance of the nut runner. Other pitches can be realized by variant construction economically.

4-fold nut runner mechanics with electrical pitch adjustment, cylinder suspension with anti-twist plate, rail system for moving. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Max. torques moments: 1.200 Nm |

|

|

Ball screw clutch system for trailer clutches

Use: Screw connection of trailer clutches balls at Westfalia

Besonderheit: Due to the high torque moments, the ball needs to be taken with a clamping force. The clamping force is made by a hydraulic chuck with 23.000 kN.

Complete mechanics with: Basic frame with protection hood and light curtain for the load range, hydraulic tightener for the clutch admission, hydraulic tension of the ball 1000 Nm, drive nut runners with torque moment and angle of rotation controller, maximum torques moments: 600 Nm |

|

|

3-fold screw connection unit with nut arrester (3-fold trailer skip)

Use: Nut running of mounting plate and semitrailer at Jost

Characteristic: The 3 nuts need to be arrested. The high torques lead with a static system to tilting. The holder is to be opened mechanically over a lever. The overall height is very limited, so that only one fork system was possible.

Complete mechanics with:

3 angle nut runners in a receiver rack, 3-fold tightener unit for nuts, supply ofnut runner to holder is made pneumatically, telescope suspension with pneumatic balancing controller maximum torque moments: 350 Nm |

|

|

2-fold bearing cover nut runners with fixed pitch

Use: Screw connection of bearing covers at diesel engines at MTU

Characteristic: The operatingl unit with the combination of tracers and lamps was developed together with the customer according to his needs. All tracers are easily attainable with the thumb of the respective hand.

Nut runner mechanics vertically, telescope suspension with rope balancer and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 950 Nm |

|

|

2-fold conrod nut runners with fixed pitch, traversable

Use: Screw connection of engine conrods on diesel engines at MTU

Characteristic: The turning of the nut runner unit is made by turning camps at the sides of the nut runner. Over adjustable friction assemblies the actuating forces for the lagging can be adjusted. Thus the nut runner can stop in each position. Nut runner mechanics inclinable over adjustable friction camps. Telescope suspension with rope balancer and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 580 Nm |

|

|

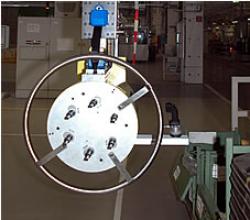

4-fold cylinder head nut runners with fixed pitch and guidance assistance

Use: Screw connection of cylinder heads on diesel engines at MTU

Characteristic: The screwing place is bent, so that an introduction assistance facilitates the supply of the nut runner unit.

Nut runner mechanics bent hung up. Introduction assistance for the positioning of the unit, telescope suspension with rope balancer and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 950 Nm |

|

|

2-fold cardan shaft nut runner

Use: Screw connection of the cardan shaft on gear and differential at

DaimlerChrysler Characteristic: The system is built out of aluminium so handling forces will be kept as small as possible. The system had to be very rigid and nevertheless mobile. By a particularly developed trick swiveling mechanism we realized the movements almost free from float. That was necessary, in order to prevent a slipping from the Torx screws during the screw connection. Additionally a pneumatic finger secured the unit at the workpiece.

Nut runner mechanics turnable, tiltable. Pneumatic finger for the adjustment of construction unit, telescope suspension with pneumatic balancing controller and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 200 Nm |

|

|

1-fold compressor nut runner

Use: Screw connection of compressors on diesel engines at DAF

Characteristic: The nut runner was not planned as multi-nut runner due to the different construction units. The reaction moments must be taken up thus by the overall system over a telescope.

Nut runner mechanics horizontal hung up. Telescope suspension with rope balancer and column swivel arm. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 150 Nm |

|

|

Robotic nut runner with nut changing system

Use: Screw connection of chillers at Bock Kältetechnik

Characteristic: This flexible automation permits to store and to work on up to 200 different construction units. The particularly laid out robot with an additional arm enables to take up it also larger torques with a relatively small robot. An automatic nut change station with up to 5 places, can take up inner hexagon socket bits, hexagon sockes, torx nutss, etc. The robot gets itself the appropriate nut for the next work procedure. Screwing robot, on the floor stand, workpiece admission with construction unit pallet admission, heights adjustably and swivelling. Complete controller for nut runners, robot, workpiece admission and nut selector. Protection device. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 85 Nm |

|

|

26-fold cylinder head nut runner with special gear

Use: Screw connection of cylinder heads on diesel engines at Caterpillar

Characteristic: The pitches of the screws were so small that even standard offset gears were too large. We developed 26-fold gear, whereby each drive received a reduction from 1:3, so that we could use smaller nut runners. Each drift has a device for the installation of a reference sensor to the contra-measurement of the torques. The entire unit becomes hand-guided with electrical support. With the weight of approx. 800 kg an automatic adjusting became necessary. Nut runner unit with 26 nut runners/special gear: Gear box out of high-strength aluminum, all pinions doubled embedded, square adapters for drive spindles, size: 1200 mm x 500 mm x 150 mm / gear reduction 1:3,5 / entrance torque max. 210 Nm / output torque max. 630 Nm, efficiency < 0.93 / repetition accuracy < 2%, Long lasting one-time grease / electrical telescope with carriage in 10 m long portal, drive over electric motors with force control.

Maximum torqu moment: 630 Nm |

|

|

20-fold cylinder head nut runners with mounting

Use: Screw connection of cylinder heads on diesel engines at Caterpillar

Characteristic: Each drift has a device for the installation of a reference sensor for the contra-measurement of the torques. The entire unit is hand-guided with electrical support. With the weight of approx. 800 kg an automatic adjusting became necessary.

Nut runner unit with 20 nut runners/electrical telescope with carriage in 10 m long portal, drive over electric motors with force control. Maximum torque moment: 630 Nm |

|

|

6-fold clutch nut runner with pitch adjustment

Use: Screw connection of clutches on gears at DaimlerChrysler

Characteristic: The system is completely built out of aluminum to keep handling forces as small as possible. With this nut runner 2 pitches for different clutch types can be mounted. All adjustment units are equipped with ball rotating guidance and lifetime grease. The adjustment takes place pneumatically.

Nut runner mechanics swivelling. Telescope suspension with electrical chain course and crossbar chassis. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 50 Nm |

|

|

4-fold U-Bolt nut runner with adjustable pitch on soil carriage

Use: Screw connection of rear axle at leaf springs at DaimlerChrysler

Characteristic: This system works soil led and is connected from downside to the screwing place. The screwing takes place from downside.

Nut runner mechanics with 2 adjustable pitches, the procedure take place on heavy load ball rotating units. The adjustment takes place pneumatically. Vertical telescope, transverse movement manually on rails, longitudinal movement on ground buses, sinked into the soil. All system components are manufactured from aluminum, the load-critical from high-strength aluminum.

Maximum torque moments: 320 Nm |