Examples wheel nut runners -

Multiple is simple in this case!

|

|

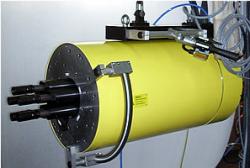

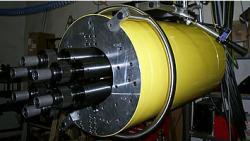

5-fold wheel nut runner with fixed pitch

Use: Bolt of wheels on trucks at DAF

Speciality: The high torque moments and the the deep immersion in the back wheel rim of the nut runner drives need an additional support extension for that standard nut runner. These support units are available for different bolt types. So the mechanics is independent of the needed bolt technology. The unit applys to the wheel by a pneumatic support. The pressure and the speed are minimised automatically short before the nut runner arives at the bolt site due to pressing the elastic key heads for the guidance of the nut runner

Bolt machanics turnable +/- 45° around the own axis

Telescope hanging with electronial chain hoist and crossbar carriage.

Pneumatic apply device for whole unit towards line.

All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium.

Support extensions for nut runner due to avoid bending force on the stanard nut runner drives.

Maximum torque moment 1000 Nm |

|

|

5-fold wheel nut runner Use: Bolt of wheels with British Leyland Nut runner mechanics swivelling around 45° around the own axle |

|

|

5-fold wheel nut runner with 4/5 hole adjustment

Use: Bolt of wheels at Volkswagen

Speciality: The system is totally built out of aluminium to reduce the operating forces as much as possible. With this nut runner you can mount 1 Pitch for 4-hole rims and 1 Pitch at 5-hole rims. All adjustment units are equipped with bowl circle guides and life time grease. The adjustment is made pneumatically.

Nut runner mechanics turnable. Telescope hanging with pneumatic balance controller and crossbar carriage All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium. Maximum torque moment: 150 Nm |

|

|

5-fold wheel nut runner with adjustable Pitch and 4/5 hole adjustment

Use: Bolt of wheels at Nissan

Speciality: The system is totally built out of aluminium to reduce the operating forces as much as possible. With this nut runner you can mount 2 Pitches for 4-hole rims and 1 Pitch at 5-hole rims. All adjustment units are equipped with bowl circle guides and life time grease. The adjustment is made pneumatically.

Nut runner mechanics turnable. Telescope hanging with pneumatic balance controller and crossbar carriage All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium. Maximum torque moment : 150 Nm |

|

|

5-fold nut runner with 4/5 hole adjustment

Use: Bolt of wheels at Toyota

Speciality: The system is totally built out of aluminium to reduce the operating forces as much as possible. With this nut runner you can mount 1 Pitch for 4-hole rims and 1 Pitch at 5-hole rims. All adjustment units are equipped with bowl circle guides and life time grease. The adjustment is made pneumatically.

Nut runner mechanics turnable. Telescope hanging with pneumatic balance controller and crossbar carriage All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium. Maximum torque moment: 150 Nm |

|

|

5-fold mobile wheel nut runner with fixed Pitch

Anwendung: Bolt of wheels on trucks at

Besonderheit: The high torque moments and the the deep immersion in the back wheel rim of the nut runner drives need an additional support extension for that standard nut runner. These support units are available for different bolt types. So the mechanics is independent of the needed bolt technology. This mobile unit is mounted on a carriabe. The whole controller is embedded. Both nut runners – right and left one – are conneced via radio communication .

Bolt mechanics turnable +/- 45° around own axis.

Carriage with telescope and crossbar carriage for the movement on X-Y-level. All system components are |

|

|

2-fold wheel nut runner with Pitch adjustment

Use: Bolt of wheels on wheel bearing at Caterpillar

Speciality: The system is nearly complete made out of aluminium to reduce the operation forces as much as possible. With this nut runner are 3 Pitches for different types of wheels mountable.

All adjustment units are equipped with bowl circle guides and life time grease. The adjustment is made pneumatically.

Bolt machanics turnable. Telescope hanging with electronial chain hoist and crossbar carriage.

All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium.

|

|

|

5-fold wheel nut runner with fixed Pitch

Use: Bolt of wheels at Volkswagen Brussels

Speciality: The system is totally built out of aluminium to reduce the operating forces as much as possible.

To movement towards the car is supported by a pneumatic cylinder.

The pressure and the speed are minimised automatically short before the nut runner arives at the bolt site so that the bolt site can be found easily and that the elastic key heads are pre-stressed a bit.

The nut runner continous working automatically after connection and afterwords it returns to the home position.

Via a multifunction grip in a joystick form you are able to start the following operations: Forward – backward / up – down / start of nut runner without encompassing

Nut runner mechanis turnable. Telescope hanging with pneumatic balance controller and crossbar carriage. Pneumatic apply unit towards the vehicle. All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium.

Maximum torque moment : 150 Nm |

|

|

5-fold mobile wheel nut runner with fixed Pitch

Use: Bolt of wheels for evaluation of parameters at DaimlerChrysler

Besonderheit: Exept the power supply, this systems works totally self-sufficient. It is made for wheel nut running with lower quantities. You can use the same nut runner for both sides of the vehicle.

Nut runner mechanics turnable +/-

45° around own axis.

Carriage with telescope and crossbar carriage for movement in X-Y level.

All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium.

Maximum torque moment : 150 Nm |

|

|

5-fold wheel nut runner Use: Fair exhibit for Atlas Copco Nut runner mechanics swivelling around 45° around the own axle Driving car with telescope and cross carriage system for the shift in XY level. All system components are manufactured from aluminum, the load-critical from high-strength aluminum. Maximum torque moment: 180 Nm |

|

|

6-fold wheel nut runner with Pitchverstellung

Use: nut running of wheels at Ford

Speciality: The system is totally built out of aluminium to reduce the operating forces as much as possible. With this nut runner you can mount 2 Pitches for different types of wheels. All adjustment units are equipped with bowl circle guides and life time grease. The adjustment is made pneumatically.

Nut runner mechanis turnable. Telescope hanging with pneumatic balance controller and crossbar carriage. Pneumatic apply unit towards the vehicle. All system components are made out of aluminium, the load-critical components are made out of high-strength aluminium.

Maximum torque moment : 320 Nm |